How our Service Works

Tell us how many cards you need

Choose your design service

Place your order

Approve your artwork proof

Upload your data securely

Receive your cards within 3-5 working days

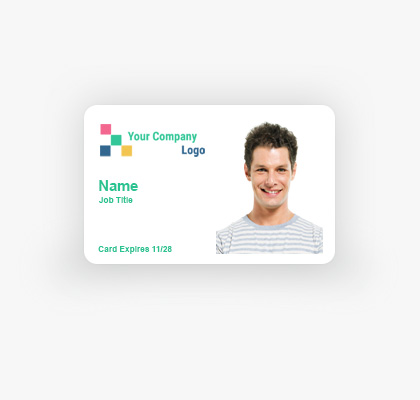

Printed ID cards

for any business sector

Printed ID cards for any sized organisation across all business sectors.

STAFF

Visually identify staff from any department with this cost-effective solution.

STUDENT

The first line of defence in stopping unauthorised personnel on campus.

SMALL BUSINESS

Over one million ID cards printed and issued to small and medium-sized businesses.

HEALTHCARE

Protecting staff, visitors and patients by issuing unclonable ID cards.

CONSTRUCTION

Instant verification to ensure workers and contractors can access sites.

Here's what

our customers say

I wish I could give 6 stars

As an integral part of our business operations, we rely heavily on the quality of service that Digital ID provide. So far to date, this has been nothing but exceptional. Owen

Why choose Digital ID

Speedy Service

We understand the urgency of having your new cards on-site asap, therefore we treat every job with the upmost priority.

Stunning Designs

Design is what we excel in. Provide our team with an existing brief or let us take the lead and get creative with your cards.

Five Star Service

We check your cards at every stage of production from our designer's desk to delivery. That's why customers rate our service "Excellent".

Handled with Care

Our team are trained to the highest levels of GDPR compliance, ensuring your data is handled correctly and securely.

Going Green

We print onto cards made from 50% recycled PVC meaning you’re playing your part in reducing your carbon footprint and helping remove single-use plastics from your supply chain.

Speed up your order by having everything prepped and ready to send.

Here’s what you need.

Download Guidelines

Frequently Asked Questions

Is there a minimum order quantity?

Yes, our minimum order quantity is 10 printed cards.

What are your ID cards made of?

As an eco-friendly supplier, we only print to cards that reduce carbon footprint and help towards lowering the need for single-use plastics.

What size are your ID cards?

Standard credit card size: 86mm by 54mm, or have a 100mm by 70mm ID card cut to a custom-size.

Can I check the design before you print my order?

Please do. Expect an email with your artwork and until you tell us to print, we won't.

How will you package my ID cards?

Carefully. For larger jobs, cards can be packaged alphabetically or by surname.

How do I supply artwork?

Securely and easily. Customers are sent a link to a dedicated page of the Digital ID website managed by our design team. Whether your artwork is a JPEG, PNG or Publisher, we will check this over and supply you with a proof to check before print.

What type of cards can you print?

Our preferred option is eco-friendly plastic cards, but we understand you may have different requirements. To accommodate this, we can print to:

• Blank plastic cards

• Access control cards with a raised surface and chip

• Rewriteable plastic cards

• Keyfob style, 2UP or 3UP

Can the cards be encoded?

They certainly can. Magnetic stripe, RFID chip and contactless encoding are available.

Can you print onto access control cards?

Yes. If you need your ID to be printed onto technology/access cards we can print cards that are compatible with most access control systems, in particular, MIFARE®, Paxton and HID.

When can I expect delivery?

Once artwork is approved, your cards will be delivered in 3-5 working days.

Choosing The Right Supplier

Choosing the right id card printing service is important - it’s essential for cost-efficiency, quality management and ensuring that you get the final product you deserve. Visual identification of staff and visitors is a hugely important matter, and shouldn’t be taken lightly. At Digital ID, we are confident that we’re the right supplier for you.

We only print and issue sustainable ID cards to our customers using cards made from 50% recycled plastic and make a conscious effort every day to reduce our carbon footprint and protect our planet from plastic pollution.

We will never be beaten on our prices - and if you do happen to find a more affordable company than ourselve’s, we’ll match it for you. Each card is checked to ensure that what we produce is nothing short of perfect. This is why we check the cards at every stage of the production process, from the designer’s desk to delivery. If you don’t believe us, check out our ‘excellent’ ratings from hundreds of satisfied customers.

As well as ID cards, we can also provide a wide range of consumables to compliment your order such as ID card holders and lanyards to keep your cards secure.